Foundations

There are many choices in foundation installation.These include newer systems that have insulation values incorporated into the form building products. Their are also standard masonry foundations or poured concrete walls.

Did you know that you can accomplish a R30 to R40 insulation value depending on your foundation wall system? Is your home being built on a crawl space or does it have a partial or full basement? Which water proofing product protects against intrusion of water and mold?

FOUNDATIONAL WALL SYSTEMS

There are many foundation systems that can meet your home requirements.

Here are just three systems from national companies with diverse types of foundation systems.

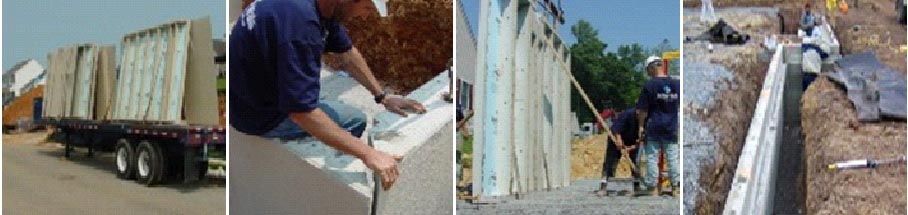

Superior Wall Systems

Today’s Smart home buyers and builders demand Walls that increase the value of today’s new homes while simultaneously increasing building precision, strength, and speed.

Today’s Smart home buyers and builders demand Walls that increase the value of today’s new homes while simultaneously increasing building precision, strength, and speed.

Superior Walls is a world leader in custom residential precast concrete foundation systems since 1981. That’s because building on a Superior Walls foundation assures architects, builders, and new home buyers their new home will create added new living space which remains dry and warm — while simultaneously meeting or exceeding the industry’s most stringent new green building

home standards.

Today’s smart home buyers care about creating comfortable lifestyles — while adding dramatic new living space and lowering their energy costs. That’s why Superior Walls are in demand worldwide as the superior foundation for every new custom home.

Discover why Superior Walls are renowned for creating added value and durability for every new home design. Discover what smart architects, builders and consumers are saying about building and living with Superior Walls: "… the highest quality… the most advanced… the strongest materials… precision design… the most efficient foundation on earth…the warmest and driest foundation… the? most green… the Superior Advantage.

Superior Wall Systems Advantages:

- Provided with 2-1/2” of insulation = R-12.5

- 5,000+ PSI concrete

- Steel reinforced with rebar and polypropylene fibers

- Pre-cast access holes for wiring and plumbing

- Thermally isolated/insulated from exterior

- Insulated corners, studs and bond beam

- Monolithically poured for maximum strength

- Galvanized steel stud facing

- Option to insulate up to R-50+

- No additional damp-proofing required

- Pre-cast openings for doors and windows

- Reduces building time

- Most projects can be installed in one day.\Ready in virtually any weather

- No footers

Superior Wall Systems Disadvantages:

- Wall systems have to be shipped via truck adding cost.

- Addition time is needed in order to plan in advance.

- Cost may exceed poured in place systems.

- Because a crane is used, in installation, experienced operators are needed.

- Damage may be caused to panels during installation or transporting.

Insulated Concrete Forms

Welcome to TF Concrete Forming Systems

Welcome to TF Concrete Forming Systems

TF Systems is a leader in the Insulated Concrete Forms (ICF) industry with a 15 year track record of proven success. TF invented the first Vertical ICF system in 1996 and has continually evolved and improved on the original vertical concept resulting in the Thermoform System® in wide use for residential and commercial projects across North America and abroad.

Most recently TF introduced an entirely new concept in concrete forming with the revolutionary Transform System™. Transform combines the best of our Thermoform vertical ICF concepts with the flexibility and industrial strength of traditional concrete forms. Best of all, Transform provides the added flexibility to pour traditional non-insulated concrete walls, super-insulated walls, or any combination; all with a forming system that is lighter, lower in cost, and more comprehensive than virtually any forming system on the market.

TF Thermo Form

TF's original forming system that brought vertical ICF to the concrete industry. Our latest improvements make it even more effective and easy to use. Homeowners, small to mid-size commercial projects and Habitat for Humanity are major users of the ThermoForm product.

Construction Costs & Project Schedule

The construction industry is renowned for running behind schedule. TF Concrete Forming Systems believes this shouldn't be the case. Their forms are designed to give the builder a competitive edge over competitors. By allowing pours in hotter and colder temperatures than other forms allow for, TF forms can extend your build season.

The construction industry is renowned for running behind schedule. TF Concrete Forming Systems believes this shouldn't be the case. Their forms are designed to give the builder a competitive edge over competitors. By allowing pours in hotter and colder temperatures than other forms allow for, TF forms can extend your build season.

With TF forms, you will complete the project faster while cutting costs. Ten years ago we built a couple a homes north of Atlanta, Georgia. The home was over 4000 Square Feet. I spoke to the owner in the spring of 2013, and he confirmed that he has paid in the range of $150.00 a Month for his heating and cooling year around. You can’t do better than that……

How?

Pex tubing that can be run through our forms allows the builder to run cool or warm water through the concrete forms immediately after a pour, keeping the concrete at optimal temperature during hydration. The result is stronger concrete and an extended building season.

Our forms are also sturdier than others, reducing the chance of collapse on a windy day, giving you peace of mind and a cost and time benefit over your competition.

Our forms are also sturdier than others, reducing the chance of collapse on a windy day, giving you peace of mind and a cost and time benefit over your competition.

TF's vertical systems also install 33 percent faster than block based horizontal ICF systems. They require less bracing and external cladding than block systems and virtually eliminate the risk of blow-outs. Walls poured with TF's forms are extremely straight and true eliminating the floating, shifting and settling problems of block based systems. You can pour with confidence and eliminate much of the time consumed with external support, cladding and taping often required for block ICF systems.

In addition rails and panels for our systems are delivered precut for your required wall heights greatly reducing waste, materials' costs, time for cutting-to-size and site clean-up requirements. TF's vertical systems are also easy to learn and install. The vertical orientation is intuitive to construction workers mimicking both traditional frame construction.

TF’s latest design, fully scalable for residential and commercial building, can operate as either a traditional, removable form system, an integrated ICF system, or any combination of both. High-end residential and commercial projects are typical.

TF Thermo Form System Advantages:

- Energy Efficiency!

- Drastically reduces energy costs

- Save on Life Cycle Costs:

- Leaves little waste

- High Thermal Value:

- Low maintenance

- High Thermal Value:

- Superior R-values greatly reduce heating

and cooling costs - Produced with recycled materials

- Saves precious energy resources

- Energy

Insulated concrete homes use sharply less energy to heat and cool—an estimated 40 percent less for heating and 30 percent less for air conditioning. This translates into monthly savings, an indoors with a more even temperature and fewer drafts, prevention of airborne contaminants, and a green building that is friendlier to the environment. An insulated concrete home is a pleasure to you and a benefit to the planet.

TF Thermo Form Architectuaral Advantages:

Design flexibility for customization

- Arches

- Step Footings

- Parapet Wall’s

- Accommodates dramatic window feature

TF Thermo Form Strength & Durability

The walls of an insulated concrete home are steel-reinforced concrete. Its strength far exceeds conventional construction. The insulated concrete home stands up much better to disasters like high winds. The walls won’t settle, creak, warp, rot, mildew, rust, or even vibrate when you slam a door. The materials don’t provide food for insects, mold, or vermin. Insulated concrete home walls are so dense they cut the amount of sound that comes in from outside by over half. Surround yourself in solidity.

TF Thermo Form Disadvantages:

- Shipping of product, as a result of plant location, needs to be monitored

- Concrete Need an experienced crew to perform Installation of product. Concrete Must be pumped because of mix required. Adding cost to the project.

Stay Connected